3D printing comes to K-W

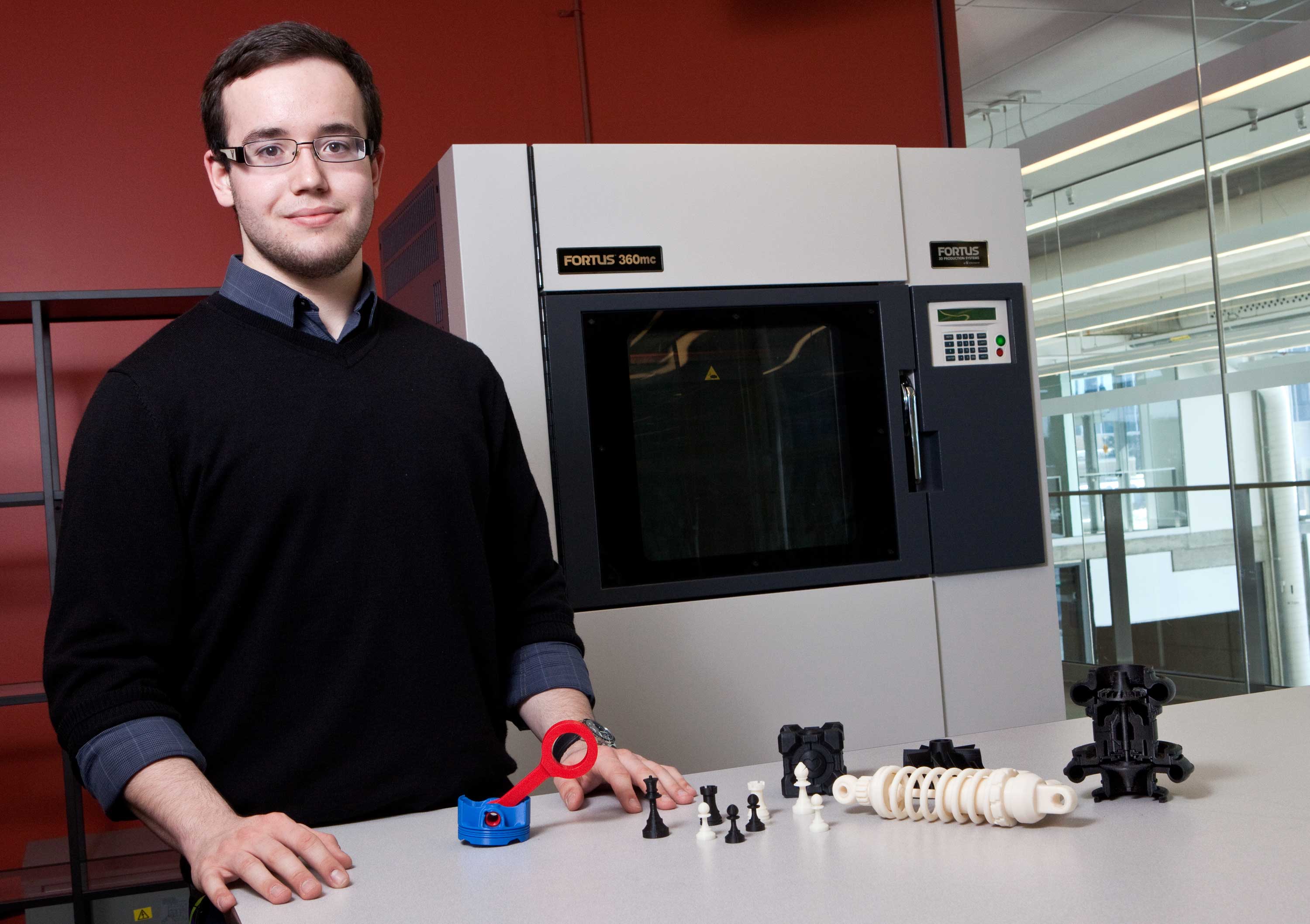

After a successful grand opening on Feb. 27, the 3D Printing Centre at the University of Waterloo (UW) is revolutionizing technology for students and faculty members.

The 3D Print Centre is a facility where students, staff and faculty at UW can access the services of a professional-grade 3D printer. Starting with a 3D computer-aided design (CAD) file, a final component can be printed using a variety of materials, colours and surface finishes.

“3D printing is not a new technology, but with reduced cost and increased final part quality, it has become much more accessible and useful to a wider segment of society,” explained Peter Teertstra, director of the Student Design Centre at UW. “We are seeing many non-engineering applications of 3D printing and hope to grow our customer base beyond engineering into science, math, art and other faculties.”

The Denso North America Foundation provided the grant money to purchase the 3D machine, while Cimetrix Solutions and Stratasys provided continued support as the centre began to take flight.

“Having access to an affordable, easy to use 3D printing service will be a huge benefit to our student teams, such as the Midnight Sun, Formula SAE and Robotics teams, along with all students working on class or personal projects,” he said. “Being able to verify that a design works, that it fits where it is supposed to, doesn’t interfere with any other parts, within a day or two allows the designer to go through several iterations until the part is right.”

He added that many of the past projects had been missing that design due to the time required to machine parts in metal. Now, the Fused Deposition Modeling (FDM) printer helps to create well-designed parts that are as well-built and sturdy as parts made using inoculation molding and other manufacturing techniques.

The 3D Print Centre is covering material costs, with no labour or machine replacement and maintenance costs.

In addition, the Centre has a trained machine operator who is an expert in 3D printing. Teertstra explained that the benefit of this is rather than an individual emailing in a CAD file with the uncertainty of receiving proper results, a student or faculty member can work with someone who is knowledgeable in 3D printing and has the capacity to help improve the overall design and the finished product.

While he is uncertain about how users will revolutionize this technology in the future, Teertstra and his team are looking forward to the future of the print centre and all it has to offer the Waterloo community.

“3D printing is an exciting new technology, and the Student Design Centre and the faculty of engineering are so pleased to be able to provide this service to our students, faculty and staff,” Teertstra said. “I am looking forward to the future when we can add more machines and more capabilities to serve what I believe will be a growing demand for 3D printing.”